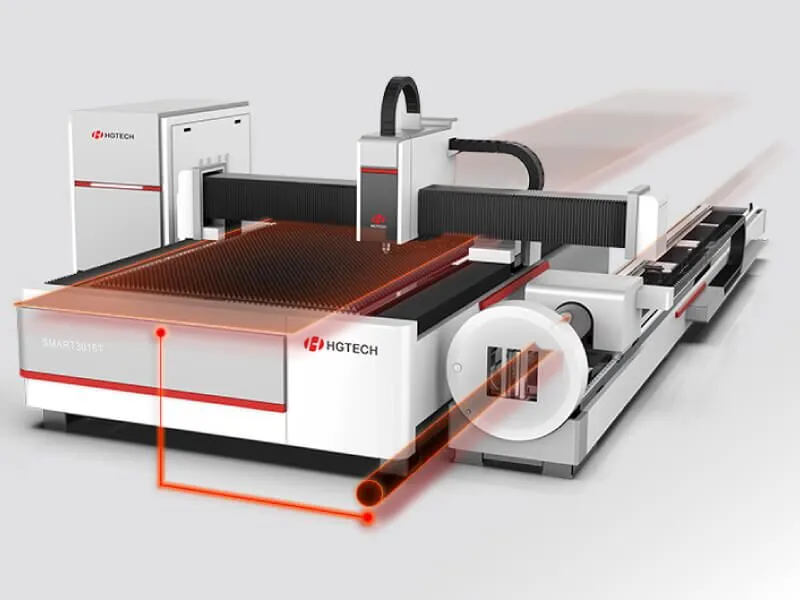

Enclosed Type Metal Sheet and Tube Fiber Laser Cutting Machine

Model: SMART Pro-T Series

Category: Enclosed Type Metal Sheet and Tube Fiber Laser Cutting Machine

Brand Name: HG Smart

Laser power: 1000W-6000W

Uses: The SMART Pro T series can quickly cut sheet metal and tubing, mostly used in the fitness equipment and furniture industries.

Features and Benefits of sheet and tube laser cutting machine

1. In the sheet and tube laser cutting machine, a Raycus 1000 Watts laser device with stable performance is used; the key parts can last 100,000 hours.

2. A sophisticated CNC control system that can directly read.ai,.plt,.dxf,.lxd, and ug code and is simple to use;

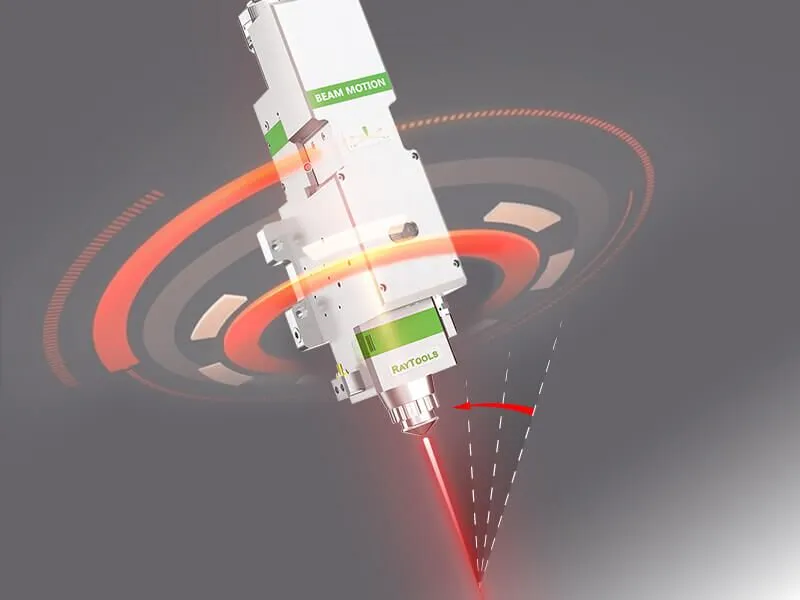

3. Intelligent cutting head with auto-height adjustment for consistent focal length and cutting quality.

4. High precision transmission device imported from Japan that works flawlessly with the servo system, ensuring cutting precision and efficiency.

The SMART Pro-T series is an improved version of the SMART series capable of cutting most sheet metals, metal plates, metal tubes, and metal pipes. Saving more than half the cost of purchasing two types of machines, doubling production efficiency, and saving more than half the workshop space.

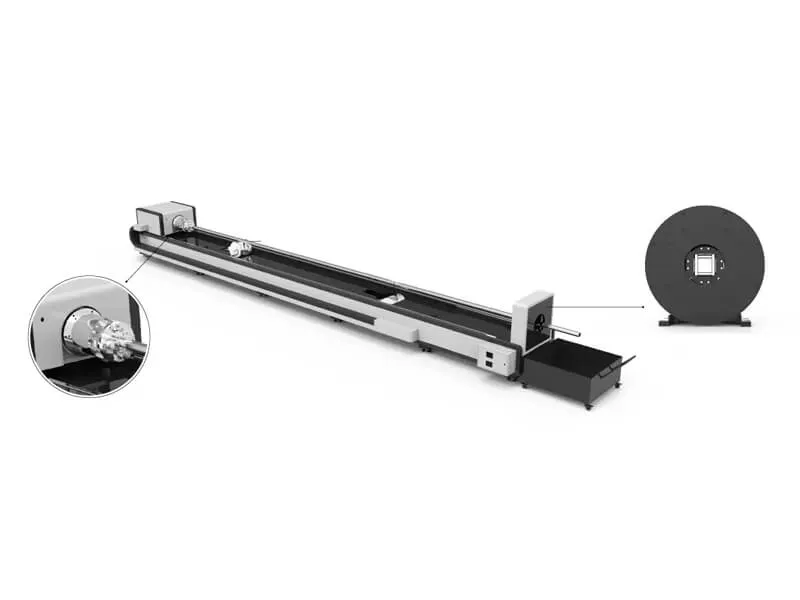

Metal tube cutting capacity is widely used in sports equipment, various types of pipe, water pipes, oil pipelines, and other industries; it can cut a wide range of special-shaped pipe materials, including round pipe, square pipe, rectangular pipe, oval pipe, and so on.

Metal sign, metal letter, metal kitchen ware, metal craft, sheet-metal work, and metal parts are all cut with an industrial laser metal cutting machine. Now is the best time to buy!

Sheet and tube laser cutting machine Parameter

Machine Model | SMART3015 Pro – T |

|---|---|

Cutting Area (L×W) | 3050mm×1530mm |

Tube Cutting size (L x dia.) | 6030mm×220mm |

Chuck size | Φ120/Φ230/Φ350 |

Laser Source | 1000W – 6000W |

CNC System | FSCUT 3000 |

Laser Cutting Head | BM111 F125mm |

Max Moving Speed | 80m/min, Acceleration is 1.0G |

Position Accuracy (X and Y axis) | ±0.02mm |

Reposition Accuracy (X and Y axis) | ±0.03mm |

Power Supply Requirement | 380V 50/60Hz 45KVA |

Machine weight | ≤8870 Kg |

Appearance size | 8930mm×4000mm×2500mm |

Sheet and tube laser cutting machine Video

Features of Industrial Fiber Laser Metal Cutting Machine

Dual Purpose and Cost-Effectiveness

Without Manual Focusing, Autofocus Laser Cutting Head

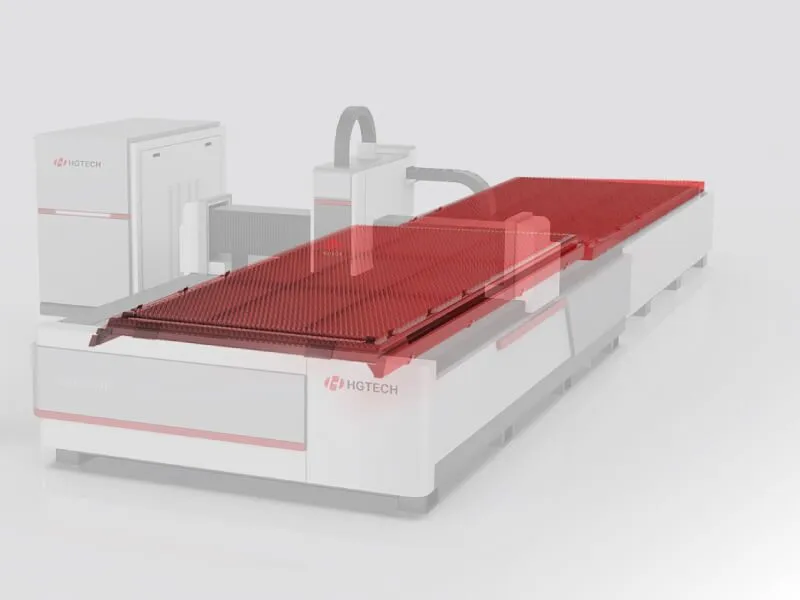

Parallel switching platform

Design of a pneumatic chuck